POURING ACCURATE MODELS

Accurate models are essential to the success of any dental laboratory or dental office because an inaccurate model will guarantee that all other phases of the restorative process cannot be done properly. There are different techniques for each type of laboratory or dental office with some similarities. Some techniques are time consuming, while others are technique sensitive. New techniques will be described to help simplify the process, save material costs and time, and ensure more consistent results.

The first step in the process of making an accurate model is pouring the impression. There are many considerations in this first step such as the type of stone to use, the water to powder ratio, the spatulation time, the vacuum mixing, and the initial set and final set times. But one of the seemingly most troublesome considerations is how to overcome the hydrophobic nature of the impression material. Just as a newly waxed car will cause water to bead and shed from the surface, an impression will resist water from flowing onto its surface. Therefore, it is necessary to use some type of surfactant to break the surface tension of the impression material. The failure to do so will lead to dimensionally inaccurate models as well as models filled with voids (often called bubbles).

Traditionally, spray on surfactants have been the most popular method of application. With this type of application, it can be difficult to produce consistent results because it is technique sensitive. Sometimes uneven amounts are distributed over the impression and either voids will occur due to the lack of a surfactant or chalky spots will appear where oversaturation of a surfactant exists. At times these types of surfactants do not reach small critical areas in the impression such as found on a prepared tooth.

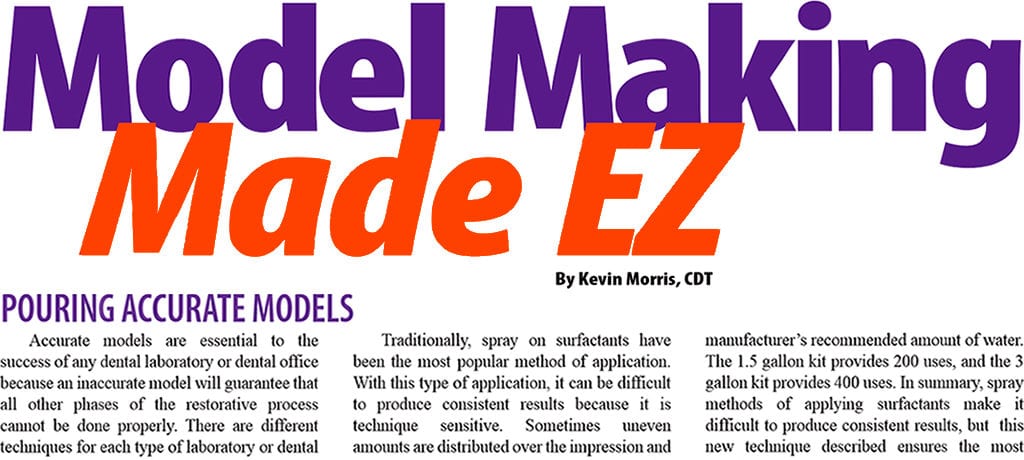

A new approach is found in the product Wonderadmix. Wonderadmix replaces the manufacturer’s recommended amount of water. When this product is used, the optimal amount of “surfactant” is distributed by the dental stone. The result is a consistent and highly accurate cast. Wonderadmix also breaks the surface tension between the dental stone and water creating a slightly harder and denser cast.

As seen in Figure 1, Wonderadmix comes with an empty 1.18 L (40 oz.) bottle and five 25 ml. syringes containing a concentration of the product. Simply empty one syringe into the bottle, fill the rest of the bottle with water, and shake well before each individual use. Wonderadmix is then ready to use in place of manufacturer’s recommended amount of water. The 1.5 gallon kit provides 200 uses, and the 3 gallon kit provides 400 uses. In summary, spray methods of applying surfactants make it difficult to produce consistent results, but this new technique described ensures the most consistent and accurate results.

TONGUE AND VOID FILLING

Another step in making an accurate model is the filling of the tongue area and voids in the impression. If the tongue area is not blocked out, the stone will flow over the edges of the tray and when the stone is set, it will become locked to the tray. If the model is pried off the tray, there is a high probability that the model will break or the impression material will tear. Sometimes there are large undercuts caused by bubbles in the impression material or because of the presence of tori. If these areas are not blocked out, impression tearing often occurs.

A few methods have been used in the laboratory to solve the problem of the tongue area. Some lab technicians and dental assistants simply cut away the tongue area while the stone is still wet. The drawback of this method is that additional trimming and basing is necessary after the model is set. Others use paper towels or Play Doh to fill in the tongue area. Paper towels leave a very rough and unprofessional looking surface which requires additional trimming to smooth. Play Doh is not heat stable and will melt during the setting of the cast. Additionally, cleaning Play Doh from the cast is difficult, and if the newly set cast is held under water to clean, the accuracy and detail is compromised.

Blocking out voids in the impression has a few methods as well. Some like to use expensive lab putty which is permanently fixed to the impression and cannot be reused. Others use some form of wax which either does not stay in place well during

vibration or poses the risk of distorting the impression because it needs to be heated and melted first.

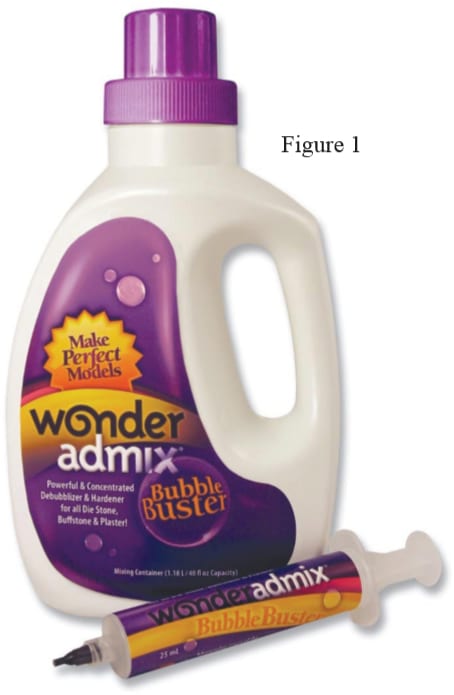

The use of Wonderfill is an alternative method for both the filling of the tongue area and the filling of voids. Wonderfill is heat stable, so it will not melt during the set time like Play Doh, and it leaves a smooth professional looking surface which requires no further work. As demonstrated in Figure 2, Wonderfill is easy to use, just remove the desired amount from the container and mold it into the shape desired. It must be noted that because Wonderfill is water soluble, excess water must be removed from the impression tray before application.

The use of this material and method saves time, material, wear of equipment, and simplifies the process.

BOX AND POUR PROCESS

Boxing the impression is the best way to insure the peripheral border of the impression is preserved as well as controlling the flow of stone and the thickness and density of the stone cast. Traditionally, there have been two methods used: the wax bead box and pour process and the plaster-pumice matrix.

The wax bead box and pour process is accomplished by surrounding the impression with utility wax and then attaching boxing or base plate wax to form the box. The plasterpumice matrix method is much more involved. First the cast is placed on a base pad suspended by some putty. Then a plaster-pumice mixture is flowed around the impression, and when it sets, it must be trimmed to the desired shape. Finally, utility wax, sticky wax, and boxing wax are used to form the box. Once the box is formed, the impression can be poured. The entire process can take 30 minutes per model.

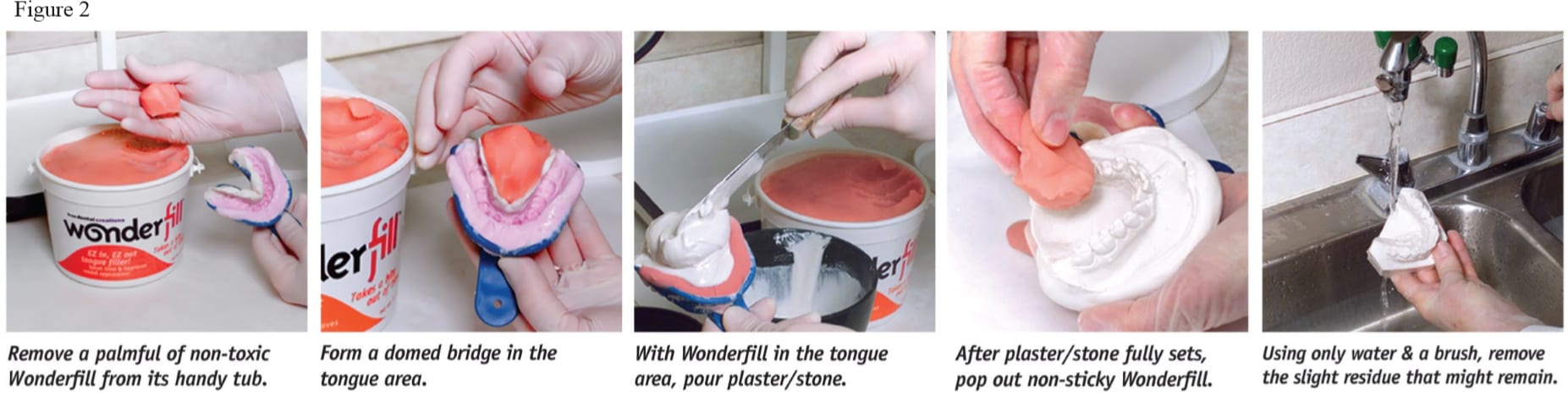

There is a new method which saves significant time and material. Wonderform casting rings are a new casting ring type boxing system. When the Wonderform casting rings are used in combination with Wonderfill, there is no need for any wax products and most of the Wonderfill can be reused several times. It is a versatile, stainless steel system which can be adjusted to accommodate large impressions or small quadrants.

As demonstrated in Figure 3, to use the Wonderform casting rings, take 10 oz. of Wonderfill and flatten it to approximately ½ in. thick and 5" in diameter. Place Wonderfill onto a 5" x 5" base pad and push the impression into the Wonderfill. Then use the Wonderform casting ring like a cookie cutter to slice through the Wonderfill and surround the impression. The impression is now boxed and ready to pour. The entire process takes only 5 minutes compared to 30 minutes for traditional methods.

The Wonder Line Products manufactured by Dental Creations, Ltd. are designed to improve the process of model making by simplifying the process and saving time and materials.

Article by: Kevin Morris, CDT

Kevin Morris, CDT, is a graduate from Diablo Valley College Dental Course and has 22 years experience as a dental technician, including owning his own lab.