There was a time that a dental technician could spend his entire career only doing two types of restorations. PFMs and full cast crowns were the bread and butter restorations for dental labs in the past. There was the occasional porcelain jacket crown, but these were difficult to make at first. The platinum foil method entailed forming thin sheets of platinum around the die and building the porcelain onto the foil. The crown would then be carefully removed from the die and fired in the furnace. When the crown was finished, the foil was removed from the inside of the restoration. If any changes were needed after the foil was removed, the technician needed more than good luck.

When the refractory die method was developed, all ceramic restorations became more popular. Veneers and inlays could be made relatively easily. I say relatively easy because this method is very technique sensitive. The refractory material must be mixed to provide the proper expansion, so when the process is finished the inlay or veneer will fit the stone cast. The refractory material must be fired prior to the ceramic stage and then rehydrated before the crown can be built. Special layering techniques must be learned for the ceramic phase and special model work techniques must be learned to pin the refractory die. Even though this technique can be labor intensive, it is still used today to fabricate feldspathic veneers and inlays which provides beautiful results.

Pressable ceramic material was the next wave, and it is still popular. With the arrival of pressable ceramics, the technique could be simplified. Traditional model work is used and then the technician waxes, presses, and finishes the crown. Ceramics can be layered or a simple stain and glaze technique can be used. Initially pressables ceramics were only strong enough for single units and those mostly consisted of anterior teeth, although some used them in the bicuspid position also. Pressables ceramics have made a larger impact with the recent development of lithium disilicate material. Now restorations can be made in both the anterior and posterior regions.

Recently there has been a large shift to the digital age

We can now scan the prepped tooth in the patient’s mouth, send the image to a milling center, have the model work milled or lazar cured, then the framework or restoration can be milled out of several materials and sent back to the laboratory. Digital technology is accelerating very quickly. Versatility of milling systems and incentives for scanners has made digital technology more desirable for smaller labs.

Something that all methods have in common is that restorations do not always fit the model work as well as desired. There are many reasons for this. Sometimes the expansion of investment materials is inaccurate. For example, maybe the cement gap during the digital design was not optimized.

Also, preparations of the tooth can be shallow and flat which makes natural retention difficult. Although there are considerations about how to correct these problems, there are also considerations about how to best stabilize these restorations during the build, firing, and contour phases.

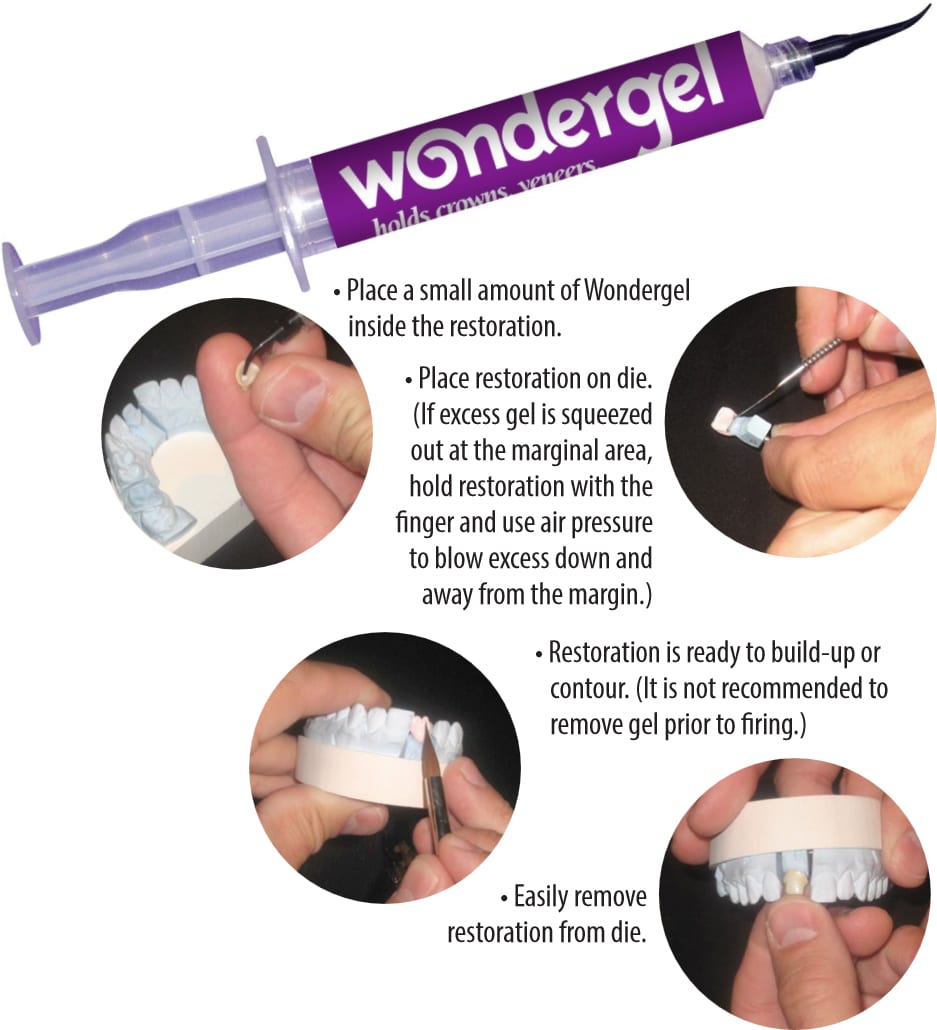

Two products have been recently developed to solve these problems. Wondergel is a clear gel which is placed on the inside of the restoration to increase the retentive quality. A small amount of the gel helps veneers and milled copings grip the die so the fabrication process is made easier. Wondergel can be used with PFMs, alumina, zirconia, and pressable ceramics, including lithium disilicate. Wondergel burns out clean in the furnace and does not leave residue.

Wonderpeg has been developed to stabilize veneers, crowns, and bridges during the firing phase. Veneers have always been difficult to fire. For example, if they are set on a pillow material, a fuzzy border where the pillow material baked into the porcelain is common. Wonderpeg is simply placed on the firing peg between the restoration and the peg. Wonderpeg holds the veneer in place during the firing cycle. Wonderpeg works well to stabilize large bridges, as well as shallow prepped restorations and small or odd shaped restorations. Wonderpeg is compatible with PFMs, alumina, zirconia, and pressable ceramics, including lithium disilicate.

With the advancement and development of new materials comes the need for new tools for the trade. Wondergel and Wonderpeg are designed to make it easier and more efficient to work with our modern materials.

Article by: Kevin Morris, CDT

Kevin Morris, CDT, is a graduate from Diablo Valley College Dental Course and has 22 years experience as a dental technician, including owning his own lab.